Remote Support for Problematic Slurry Pump Installation

At T-T, we are committed to providing effective technical support to clients at every stage of their journey. From advising on pump specification to walking you through control panel resets, our experts provide constructive solutions that get your equipment performing as it is designed to.

No effort is spared when it comes to supporting our clients, as evidenced by the recent case of a problematic slurry pump installation in Chile, South America.

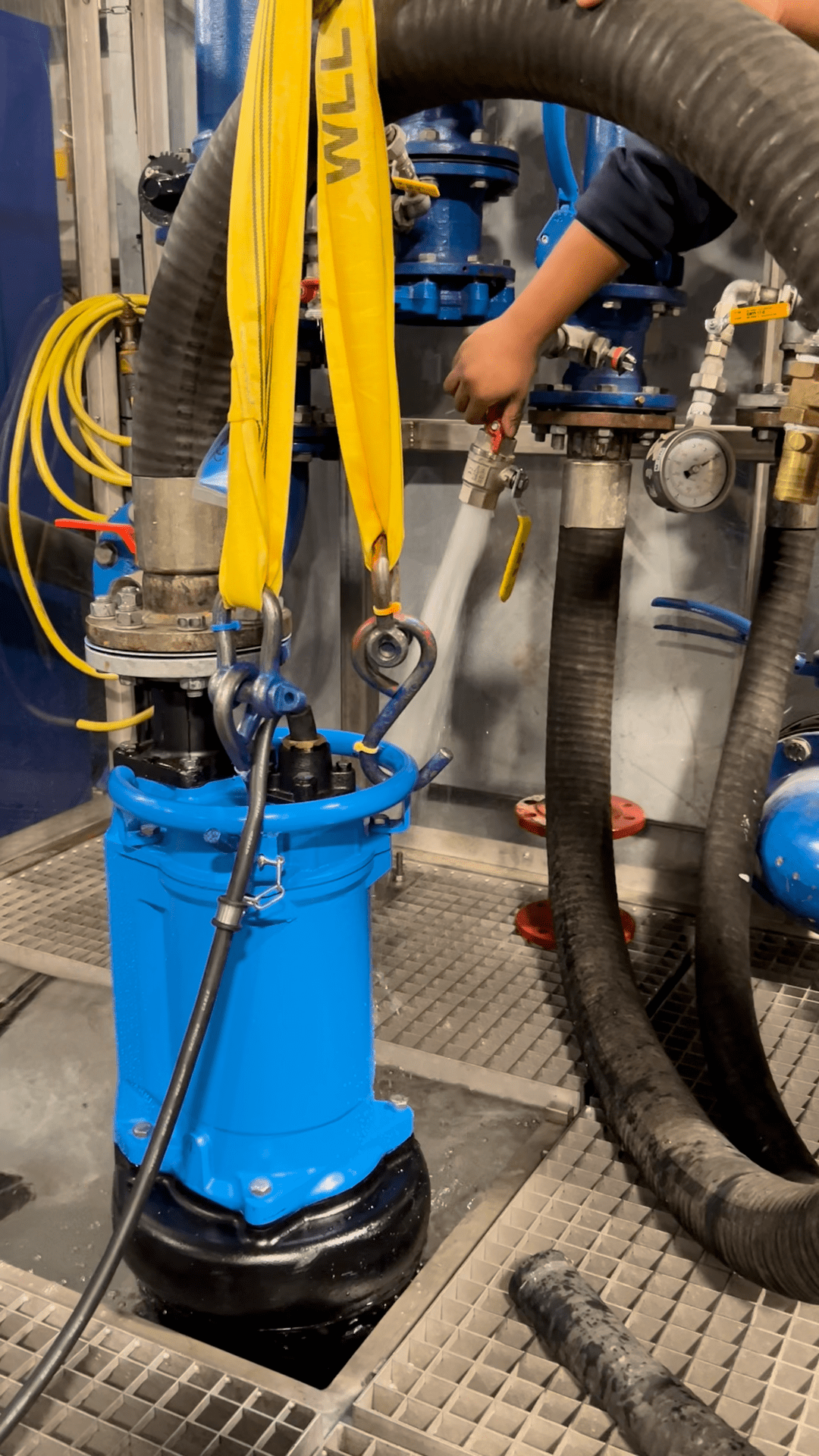

A KTA slurry pump with modified agitator was purchased for installation into a settling tank, where it would form part of a wastewater recycling system.

After installing the pump and switching it on, the client informed T-T Pumps® sales engineers that there was no flow coming through the pump’s discharge hose. The team quickly obtained another KTA from stock at HQ and completed electro-mechanical tests in-house to ensure correct operation before it was air freighted to Chile.

Site engineers reported that the issue persisted with the newly delivered pump – being the second pump to have a perceived malfunction with testing prior to despatch highlighting no issues, the T-T Pumps® Sales Management team jumped on the case to begin troubleshooting the source of the issue.

Due to the site’s location, troubleshooting instructions and results had to be relayed remotely. Clear communication was crucial to ensuring engineers in Chile understood the checks they were asked to undertake and then our team understanding the results. With a language barrier impacting the clarity of verbal communication, a live document was established where both parties could leave and respond to comments in their native language and translate comments left by the other team.

Our experts started by providing step-by-step installation instructions to rule out issues such as component misalignment or incorrect incoming voltage affecting pump operation. When reinstallation didn’t remedy the issue, the site team were asked to send video footage of electro-mechanical checks for our team to confirm correct pump operation, like checking the direction of impeller rotation.

Videos sent by site engineers showed the slurry pump kicking in the correct direction upon starting and all components working as expected up until the point of discharge. With no missteps in the pump’s installation or operation, and testing at HQ not highlighting any faults, our team were confident that the problem was rooted in the application rather than being a fault of the pump.

With the distance to site preventing attendance, our team were reliant on information from the client’s engineers in locating the source of the issue. Suspecting that they were missing a key part of the puzzle, potentially something the engineers hadn’t noticed, the team organised a video call with the site’s Managing Director to see the pump in operation and inspect for anomalies.

During the video call bubbles could be seen in the water at the base of the pump and cavitation sounds could be heard along with the pump motor – combined with the absence of flow through the discharge, they deduced that the pump could be air locking.

In order to provide a swift and effective resolution, the team wanted to confirm their theory before proposing any fixes to the client. Despite being set to close for the day, within half an hour of the call ending Engineers in the T-T Workshop had simulated the client's system on our test rig and installed a KTA from stock to try and replicate the issue.

Exact conditions were reproduced by lifting grates from the bottom of the test rig and filling it with water to mirror tank levels on site, with a discharge hose attached between the pump and a tap to monitor the flow of water.

Turning the pump on confirmed the team’s air locking theory – water levels in the tank were too low, causing the pump to intake air with water, this air was then accumulating and blocking the pump’s discharge.

With an answer to the problem and a solution in hand, the pair contacted the site’s Managing Director to demonstrate the issue and explain that adjusting their system to maintain a set minimum tank level would prevent air from entering the pump.

Our engineers recorded a video of the pump on our test rig for the client to refer to in future installations:

- The tank was initially filled so that the water level sat above the pump’s inlet,

- The pump was switched on and water can be seen flowing through the discharge pipework attached to the discharge hose,

- The pump continued to operate until water levels in the tank fell below the pump inlet, at this point air bubbles and cavitation sounds began and water stopped flowing from the discharge pipework, signalling that the pump had airlocked.

KTA pump operating on test rig, pumping water through the discharge outlet.

KTA slurry pump still operating but showing bubbles in the water, flow had stopped at this point.

Close up of air bubbles at the pump inlet, showing that the KTA is drawing in air.

The team were relieved to have found the source of the problem and a successful fix for the client, made possible by the dedication of T-T team members; a healthy stockholding of products at HQ; and a test rig designed and manufactured by our own skilled engineers that provided a controlled environment for the pump to be tested.

For support that goes above and beyond – from production specification to long-term technical support – contact T-T, where we have the facilities, technical ability and commitment to ensure the success of our customers at every step of their project.