How-to: Install a Below Ground Package Pumping Station

The Pluto® is a smaller member of our Planet® Range of package pumping stations, sized for the following applications where use of mains gravity drainage is not possible:

- Domestic sewage and surface water

- Basement, cavity wall and damp drainage

- Small domestic foul water applications, e.g. extensions and annexes

All of our package pumping stations are supplied to you fully assembled, with pumps and pipework in place so that it can be installed upon delivery.

We also set the included float switches in a standard level control arrangement (though this can be adjusted) and ship all cables left coiled inside of the tank, ready to be pulled through the cable ducts.

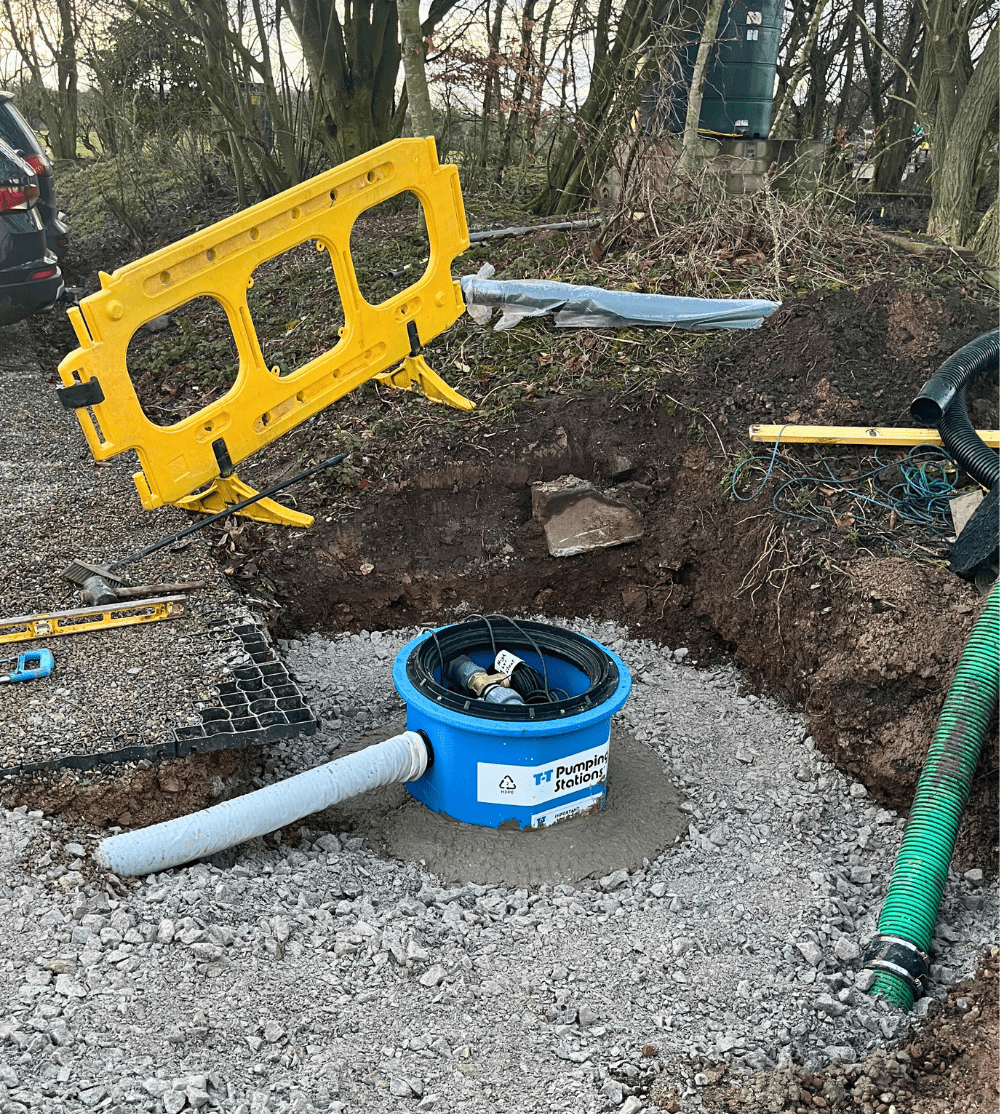

Each station is supplied with a comprehensive manual that details the exact installation procedure, but we’ve put together an overview to show you how easily a Pluto can be set up, complimented with photos from a station recently installed at T-T HQ for surface water drainage.

This is not a detailed installation guide, for complete step-by-step instructions please always refer to the manual supplied with your Planet® Range package pumping station.

Site Design

Before you begin excavating a spot for your Pluto® chamber, there are a number of factors that will help determine the best spot for installation. Careful planning can save you a lot of time and effort later on!

1. Will the chamber be accessible?

Domestic pumping stations are generally located at the lowest ground level of a site as this is the most effective place for collecting drainage water. However, the location of the chamber and cover slab must also be unobstructed to permit easy access for inspection and maintenance.

2. Will incoming pipework have a sufficient gradient?

Pipework leading into the station’s chamber must have a steep enough gradient for wastewater to reach self-cleaning velocity. This is the minimum velocity that water must travel to keep solids suspended, preventing sedimentation and eventual pipework blockages.

3. Will the power supply accommodate voltage drop?

Voltage drop is a decrease in voltage in electrical circuits as electricity moves through components like wires, switches and resistors. Careful cable sizing can mitigate this, as larger cables pose less resistance.

4. Will the inlet and rising main pipe work be sufficiently buried underground?

Pipework leading into and out of your package pumping station needs to be buried at the depth recommended by the product manufacturer – also refer to Approved Document H (Drainage and Waste Disposal) of UK Building Regulations for further guidance.

5. Are the strength and condition of the ground suitable for the installation?

If the ground is unstable, i.e. peaty and with a low bearing capacity/high compressibility, then the base may need strengthening prior to installation. The weight of the pumping station access cover must also be considered.

Contact a structural or drainage consultant if you are unsure.

Pre-installation checks

Before getting your pumping station in the ground, make sure you have completed the following checks of your Pluto®:

- Visual checks – Carefully inspect the unit for any signs of damage as this could compromise the integrity of the polypropylene chamber, such as dents and scratches.

- Secure fittings – Despite being assembled prior to delivery, it is best practice to double check that all fittings and attachments are securely fastened for safe and efficient operation.

- Excavation safety – If the ground you are excavating is unstable, shuttering may be required to prevent the walls from collapsing in.

- Base slab – Ensure the base slab is completely level and the concrete has fully set prior to installation, otherwise the station’s performance and structural integrity can be compromised.

Every package pumping station receives a thorough pre-delivery inspection from our team to ensure that the chamber and all of its internal components are in good condition and correctly installed – however on occasion, items can become loose or sustain damage during delivery.

If this is the case, please contact our pump sales team for support: 01630 647200 or pumpsales@ttpumps.com.

Installation

For your safety and to ensure proper procedures are followed, we highly recommend that you engage the services of qualified civil engineers/building contractors to manage the installation of your pumping station and pipework connections, and a competent electrical contractor to establish power supply, connection and cabling.

STEP 1: Excavation

For the Pluto® without extension turret, excavate an area 1000x1000mm with a minimum depth of 855mm to accommodate a base slab. For chambers with extension turrets, the minimum depth must be 1250mm.

Trenches for connections must also be made, including the rising main, inlet pipes, cable duct and vent pipe.

NOTE: It is crucial that the excavation is kept dry throughout the installation process to protect its structural integrity and the strength of the concrete backfill; otherwise the chamber could suffer irreparable damage. For site’s with high ground water drainage pumps will be required.

STEP 3: Rising Main & Inlet Pipework

Once the base is fully set, lay the rising main, inlet pipes, cable ducts and vent pipe in the position required by the site layout.

STEP 2: Base Slab

Once the excavation is complete, prepare the ground for pouring the base slab. We recommend a minimum base thickness of 200mm as this provides enough materials for the fixing of anchors to secure the tank.

STEP 4: Place Tank

With the excavation completed, the base slab dry and all relevant connections made, it is time to mark up the tank. Place the tank into the excavation, aligning the chamber’s outlet adaptor with the rising main and marking entry points for all other incoming pipes and ducts. Next, mark the position of fixings on the base slab.

STEP 5: Inlet Pipe Holes

Remove the tank from the excavation. You will need to cut a Ø125mm hole in the tank for the Ø110mm inlet pipe sealing ring connections and a Ø64mm hole for the 2” cable duct/vent pipe. With the holes cut in the chamber, it can be placed back in the excavation and affixed to the concrete slab.

STEP 6: Connect Inlet Pipes

Connect the inlet pipe through the seal, the pipe may need some lubrication to slide through the seal. Once in, ensure the pipe is supported to prevent movement and seal compromise and check that the end of the pipe/duct doesn’t protrude more than 10mm inside the tank as this can obstruct the movement of float switches.

STEP 7: Concrete Backfill

With the pump station chamber, pipes and ducts secured in place, as well as cables pulled through the cable duct for connection to the control panel, completely fill the tank with clean water to check for leaks and then begin the concrete backfill wet pour.

The Pluto® tank requires a minimum depth of 200mm concrete around it, we recommend a maximum concrete backfill wet pour of 500mm with the chamber completely full of water.

Depending on the height of your pump station/whether you are using a turret, you may need to complete the backfill in two stages. We recommend concrete backfills to be completed in 1m increments.

STEP 8: Access Frame

When the concrete backfill has set, grout up the remaining opening to FFL and secure the access cover in the frame.

STEP 9: Floats & Electrical Connections

Make sure that the float switches are hanging freely within the tank for unobstructed movement with tank water levels and that all cables are pulled through to the motor control panel. Be careful to leave enough slack within the tank so that cables can be manoeuvred during maintenance and servicing.

Pull cables through locally for final electrical connections.

NOTE: If ordered, we preset your float switches before delivery to provide an estimated start, stop and high-level setting to suit the depth of the chamber. However, these points can be changed by altering where the float’s cables are secured – if you want to change the position of float switches, please first contact a member of our team for advice.

STEP 10: Commissioning

- When you are happy that all of the station’s connections (electrical? Pipes?) are correct, following these steps to perform a test run of the system:

- Single pump system – Lift the duty float into its start position, you should notice that the pump begins operating. Do this for only a few seconds before returning the float to its stop position to turn the pump off.

- Dual pump system – Repeat the steps above twice, you should notice that a different pump operates each time. This shows that the stepping relay in the control panel is operating correctly.

- High-level alarm – For Pluto pumping stations supplied with a Libra Micro panel, lift the duty float switch to its on position and hold it there until the high-level alarm sounds. Adjust the timer to suit the inflow needs of the application and prevent false alarms. For Pluto’s supplied with a T-T Alert and integral float switch, lift the duty float to its high position and the alarm feature on your panel should activate.

More detailed installation instructions can be found in the manual supplied with your Pluto® package pumping station, however if you need support or technical advice at any stage of your installation, please contact a member of our team who will be happy to assist you.