How-to: Protect your Pump Station from Blockages & Breakdowns

With a typical pipeline diameter of 100mm (4"), domestic pumping stations are designed to pump three things: pee, poo, and (toilet) paper.

Unfortunately, various other items are disposed of down toilets and sinks every day, causing completely avoidable pump and pipeline blockages. These blockages then lead to pumping station component failures and complete breakdowns, which can result in more serious problems if the station's chamber overflows, such as flooded homes, pollution of nearby watercourses, hefty environmental fines and clean-up costs.

How to Dispose of Unflushable Items

Here are some handy tips on how to dispose of items that we regularly find blocking pumping stations:

- Cooking Fat - Allow the fat to cool and solidify, then scrape it out; wrap it into some newspaper or tin foil and dispose of it in your appropriate bin. Alternatively, pour it into a suitable container and when it has cooled throw it in the appropriate bin.

- Sanitary towels, tampons and panty liners - Wrap well and place them in the appropriate bin. Special disposal bags are available at pharmacies and supermarkets. In public toilets place them in the sanitary disposal bin provided.

- Condoms, incontinence pads, used plasters and bandages - Wrap well and place them in the appropriate bin.

- Disposal nappies, liners, and wipes - Wrap well and place in an appropriate bin. Nappy disposal bags are available in supermarkets.

- Razor blades - To avoid injury, place razor blades in a solid container before placing in the bin.

- Medicines - Return all unused medicines to your local pharmacy for safe disposal. Always keep medicines out of the reach of children, even when disposed of.

- Used syringes and needles - Needles and syringes should be taken to your nearest disposal bank. Your doctor or pharmacy should be able to find your nearest disposal bank.

- Earbuds and flossing sticks - Dispose of in an appropriate bin. Plastic is a worldwide issue and things like earbuds and flossing sticks can break down into small fibers and make their way through the water system.

- All other waste - Wrap well, if necessary, and dispose of it safely in your bin. For all other liquids and items contact your local council for details of your nearest household waste recycling centre.

Download our Don't Rush to Flush leaflet to share with friends, family, residents and more!

Regular Pumping Station Service

Regular servicing of your pumping station will keep all of its vital components in top operating condition and help to prevent breakdowns. A pumping station service generally consists of cleaning, which reduces the risk of blockages that can affect the station’s performance and cause damage to pumps, valves and impellers; and electro-mechanical checks that ensure all parts are working efficiently and allow engineers to spot and replace damaged equipment.

We recommend implementing a regular service routine to improve the lifespan and energy efficiency of your pumping station – for sewage pump stations we recommend a 6-monthly service.

T-T Service® offers Pump Maintenance Packages that can be customised to suit the needs of your site, with a team of Service Engineers that provide servicing, maintenance and emergency breakdown response across the UK. Find out more about Pump Maintenance Packages or contact a member of the team for a free, no-obligation quote and expert advice.

Pump Station Monitoring

Pumping station monitoring and telemetry (recording and transmitting readings from a piece of equipment) is the best way to keep an eye on the operational status of your station and implement proactive maintenance.

Seer® remote monitoring from T-T Controls® uses cloud-based technology to continually communicate the status of your pumping station in real-time, with live updates and alarms that can be personalised to your needs – such as a level sensor at high-level or overheated pump alerts.

Seer® also stores historical pumping station data that can be accessed, analysed, and compared to live data. This highlights changes in pumping station performance and informs appropriate maintenance to resolve the issue before further damage or a breakdown can occur. For example, if it is taking longer for low-level to be reached once the station’s pumps have been activated, this could be indicative of a worn pump impeller or stuck non-return valve that needs addressing.

Seer® Monitoring services can be included in Pump Maintenance Packages for your peace of mind, including weekly status reports – speak to a member of the team for more information.

Choose the Right Pumps

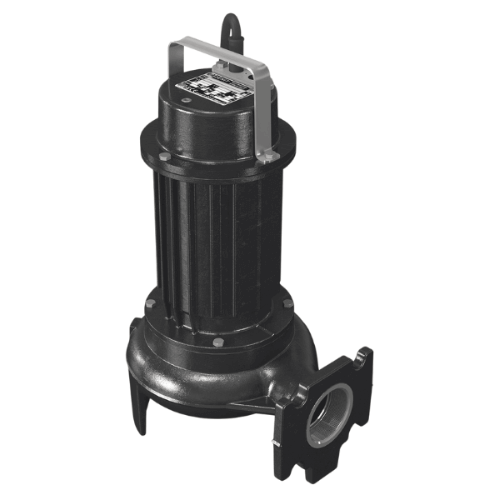

Choosing the right pump or pumps for inside your station’s chamber is essential to effective waste management and minimising the risk of breakdowns. The pump that will perform best in your station depends on the kind of waste it will be handling – such as stormwater, sewage, treated effluent or manufacturing waste (think food, pulp and paper) – and the operating parameters (flow rate and maximum pressure) needed to reliably transfer waste to the appropriate outlet.

When selecting pumps, choose ones that can perform just above the flow and pressure levels required by the site to ensure they will not become overwhelmed; this is called oversizing. Be careful not to oversize too much, as installing pumps that perform much further above the required level can cause energy inefficiency and increased operating costs.

Different pump models are designed to handle media with different sizes and kinds of suspended solids. Some pumps have higher free passage to allow suspended solids to pass through, some have agitators that stop solids from settling and causing blockages, and some have additional chopping and grinding mechanisms that reduce the size of solids prior to pumping. Chopper and grinder pumps are best for waste containing fibrous solids such as wet wipes, as these can cause ragging and decrease the pump’s hydraulic efficiency.

Our experts in T-T Pumping Stations® are more than happy to help you find the perfect pump for your private or adoptable station – contact the team or complete our online enquiry form for help.

Commonly Asked Questions

What are the signs of a pump running dry?

- Signs that your pump is running dry include:

- The pump case warping due to overheating

- Unusual noises when the pump is running

- A drop in performance, such as the pump no longer achieving the required discharge flow rate

- The pump control panel tripping due to overheating

How does cavitation affect pump performance?

Pump cavitation, when bubbles form and collapse within a pump due to a drop in fluid pressure, causes reduced pump performance and loud vibrations which can lead to damage of the pump impeller, bearings, seals and casing.

How can I reduce pump blockages?

Implement a regular service schedule – pump servicing includes checking and cleaning the inside of pump and will help to prevent solids from building up and causing a blockage. We recommend two services a year.

Complete regular audio/visual checks of your pump and its output – if the pump’s operating noises are different than usual, or the discharge flow is reduced, it could be a sign of solids building within the pump.

For more information about keeping your pumping station free of blockages and breakdowns, or to discuss monitoring and pump maintenance packages, contact a member of the team by calling 01630 647200, emailing response@ttpumps.com or completing our online enquiry form.