How-to: Select Valve Operating Equipment

Valve operating equipment, or valve actuators, are devices that adjust a valve’s position between open and closed. These devices can be either manually or automatically operated, with options for electric, pneumatic and hydraulic power sources.

When valves are installed in inaccessible or hazardous areas – such as below ground or in enclosed spaces – valve actuators allow for safe and efficient operation from a remote and ergonomic position.

Actuators can also provide the benefit of increased torque output for operating large and remotely placed valves, as well as reducing valve actuation speed to minimise the risk of damaging valve slam and water hammer occurring from rapid system pressure changes.

What to Consider

There are many types and configurations of valve operating equipment, all of which are best suited to different kinds of applications. To help determine which valve actuation method will work best for your system, start with the below considerations:

Valve design

Larger valves often require more force, making manual operation a potential health hazard, whereas smaller valves or valves fitted with actuators that increase the input torque are suitable for manual use.

Valve cycles (the complete process of a valve opening and closing) are either quarter-turn (90 degrees) or multi-turn (above 90 degrees). Quarter-turn valves are best for quick operation and system isolation, so automatic or lever operation would offer the fastest actuation. Multi-turn valves require a number of turns to complete a cycle and allow for more precision, a handwheel or automated gearbox and position indicator would offer the most control.

Valve location

If installed below ground, accessories such as extension spindles and valve boxes will be needed so that the valve operating stem can be adjusted from above ground. The installation environment will also determine whether the valve is actuated manually or automatically, because some power sources may not be available or safe for use in the area.

System pressure/speed

The chosen actuation method must be able to provide the torque required to overcome the maximum expected pressure rating of the system to ensure reliable closed seals.

Matter properties

If the application’s matter has high viscosity the valve operating method will need to provide a higher torque output in order to overcome the fluid’s resistance and close reliably.

Operation frequency

For frequently adjusted valves, especially larger ones, automatic actuation is safer and more convenient than an operator continually applying manual force.

Actuation Methods

T-Key

T-keys are manual valve actuation tools with a T-shaped body and a square socket (female) at the end. This socket accepts a square-shaped protrusion (male) on the valve, and when the T-key is turned, it transfers the torque to operate the valve.

T-keys are simple, lightweight and generally low-cost actuation devices, ideal for manual and remote valve operation when used in conjunction with accessories such as extension spindles and valve surface boxes – generally used with smaller valves.

Handwheel

Handwheels can be fixed straight to a valve’s stem, extension spindle or gearbox. Handwheels offer more precise actuation for multi-turn valves that are intended for flow throttling rather than complete isolation. When used with torque-increasing gearboxes handwheels can be used to operate larger valves.

Lever operated

The lever completes a full valve cycle in a single movement, designed for quarter-turn valves that need faster actuation.

Gearbox

Gearboxes are mechanical devices that use gears to transfer torque to a valve stem for actuation, they can be operated manually (via a handwheel) or automatically (such as motor driven) and are best suited to multi-turn valves.

Gearboxes provide a mechanical advantage to both automatic and manually operated valves – the chosen gear ratio (number of teach on the input gear vs the number of teeth on the output gear) can either increase output torque and decrease output speed or vice versa. This can be customised within your gearbox to provide the desired speed or force needed to operate the valve.

Different gearbox designs offer different benefits to a range of application and valve types. T-T offers the following:

- Bevel gearboxes: designed for transferring torque between a valve shaft and actuator that are aligned at an angle to one another.

- Spur gearboxes: designed for transferring torque between a valve shaft and actuator that are aligned in a straight line.

- Reversing spur gearbox: engineered to reverse the output direction of the turning motion regardless of the input direction ?more?

Actuation Accessories

Extension spindle – a shaft that extends the reach of a valves operating mechanism, bridging the gap between a valve stem and actuation handle to allow for remote and safe operation. They can be operated with T-keys, handwheels and gearboxes for both manual and automatic actuation.

T-T offers one and two piece extension spindles in a range of sizes and with standard male/female couplings to suit valve caps designed to BS5163. We also custom fabricate spindles with bespoke couplings to accept any valve stem termination, utilising intermediate coupling and gaitered universal joints to accommodate offsets within the extension spindle.

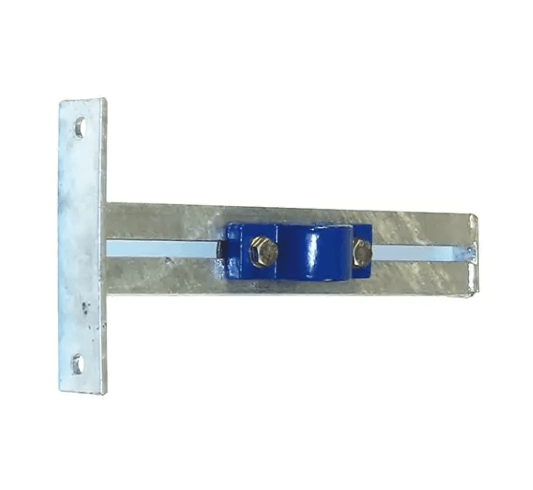

Support bracket – T-T’s adjustable outreach brackets offer support to extended valve spindles in a range of sizes, offering increased system safety and reducing potential spindle and valve damage.

Floor Mounted Pedestal – floor mounted pedestals are a means of securely mounting valve operating equipment, such as a gearbox, above ground. An extension spindle attaches to the valve shaft via a female coupling and terminates at the top of the pedestal with your desired actuation method.

Surface box – a structure used to protect and provide access to remote valve operating components such as an extension spindle or gearbox.

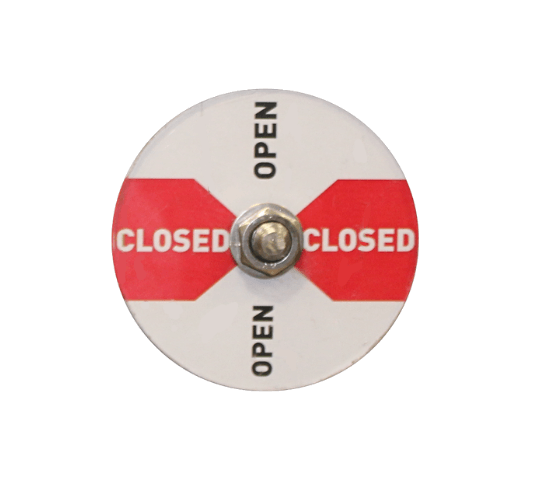

Position indicator – valve position indicators come in a range of designs, but their basic function is to show whether a valve is in an open, closed or intermediate state.

T-T Flow®, bespoke valve actuation

The engineering experts in T-T Flow® custom design and fabricate valve operating equipment to suit the needs of any valve and application, with construction materials ranging from carbon steel to duplex stainless steel for strength and corrosion resistance.

Contact our offices today to discuss bespoke actuator fabrication to suit your site’s needs or for expert selection advice – call 01630 647200, email ttflow@ttpumps.com or complete our online enquiry form.